Metal fabrication precisely and rapidly

176

24

82

6000+

Certifications

ISO 9001:2015 | IATF 16949 Registered | ISO 14001

- Craft 2

Laser cutting and bending

Available size

Can make these metal parts:

Thickness from 0.5 mm to 15mm,

Length or width size is from 20mm to 3000 mm.

Advantages

No tooling charge, fast samples lead time.

Suitable for bigger parts, and whose design is not decided.

- Craft 1

Metal Stamping

Available size

Can make these metal parts:

Thickness from 0.1mm to 6 mm,

Length and width from 2mm to 2000mm.

Advantages

Steady quality, lower unit price, fast production efficiency.

Classification

(1) Single punching:

Suitable for parts, whose size is bigger, structure is more complex ;

tooling price is competitive, good option for small MOQ and limited tooling budget.

(2) Progressive punching:

Suitable for precision parts, fast lead time, competitive unit price,

good option for big MOQ.

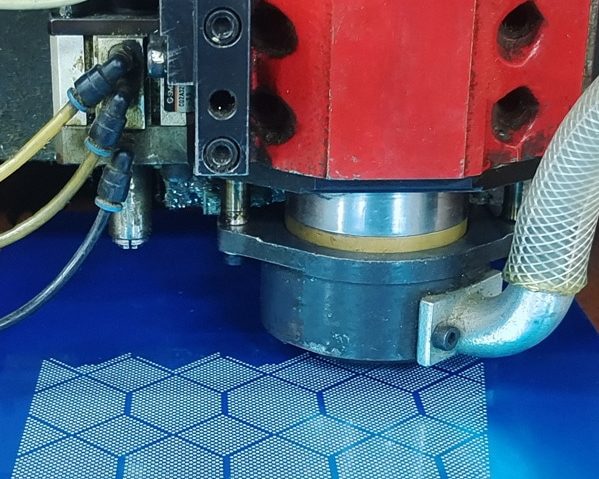

- Craft 3

Craft for meshes

Classification

(1) Etching:

Available material:

Copper/ Iron / Steel / Stainless steel/ Aluminum

Holes shape

Round, square, elliptical, triangular, hexagonal……

(2) High speed drilling:

Can make round holes, for material Aluminum and Stainless steel.

Advantage:

Lower cost, fast lead time, good for environment.

- Craft 1

Metal Stamping

Available size

Can make these metal parts:

Thickness from 0.1mm to 6 mm,

Length and width from 2mm to 2000mm.

Advantages

Steady quality, lower unit price, fast production efficiency.

Classification

(1) Single punching:

Suitable for parts, whose size is bigger, structure is more complex ;

tooling price is competitive, good option for small MOQ and limited tooling budget.

(2) Progressive punching:

Suitable for precision parts, fast lead time, competitive unit price,

good option for big MOQ.

- Craft 2

Laser cutting and bending

Available size

Can make these metal parts:

Thickness from 0.5 mm to 15mm,

Length or width size is from 20mm to 3000 mm.

Advantages

No tooling charge, fast samples lead time.

Suitable for bigger parts, and whose design is not decided.

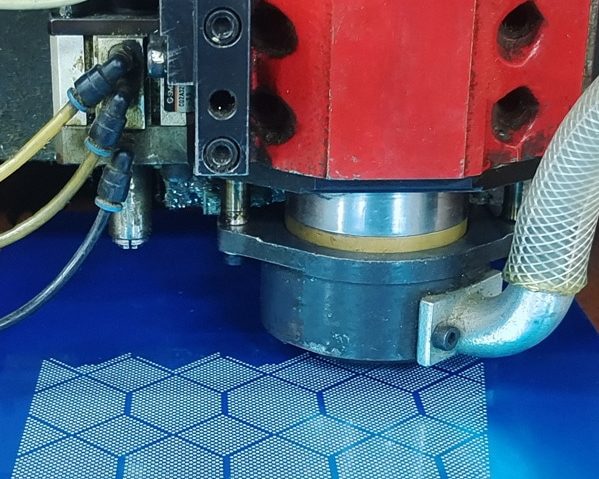

- Craft 3

Craft for meshes

Classification

(1) Etching:

Available material:

Copper/ Iron / Steel / Stainless steel/ Aluminum

Holes shape

Round, square, elliptical, triangular, hexagonal……

(2) High speed drilling:

Can make round holes, for material Aluminum and Stainless steel.

Advantage:

Lower cost, fast lead time, good for environment.

Customer feedback

Company Introduction

Why choose Taihe ?

1. OEM :

R&D team can offer craft improvements, 10 among of them got patents;

2. Quality :

Have completed testers and QC system, PPAP and IMDS are available, after 100% Full inspection, defective rate ≤ 0.002%.

3. Cost:

With Integrated supplying chain, based on objective and scientific system, every cost is controlled strictly.

4.Lead time:

Be fast and punctual, with the help of steady tooling quality, accurate production plan, specially- assigned following up, and system management.

5.MOQ:

Flexible crafts available, choose best one according to different MOQ.

6.Service:

Stand at the point of customers

Clients we are supporting